Rechargeable batteries that provide increased specific energy and improved safety over commercial Lithium ion batteries (LIBs) are in demand for applications such as electric vehicles (EVs), all-electric aircraft and the grid-scale storage of electricity from renewable but intermittent electrical generation.

Inventors at King’s College London and Oxford University have come up with novel type of rechargeable solid-state battery (SSB) technology that addresses the two key limitations in this field namely safety and higher specific energy.

Solid-state Li metal batteries (SSLMBs) combine improved safety and high specific energy that can surpass current Li ion batteries.

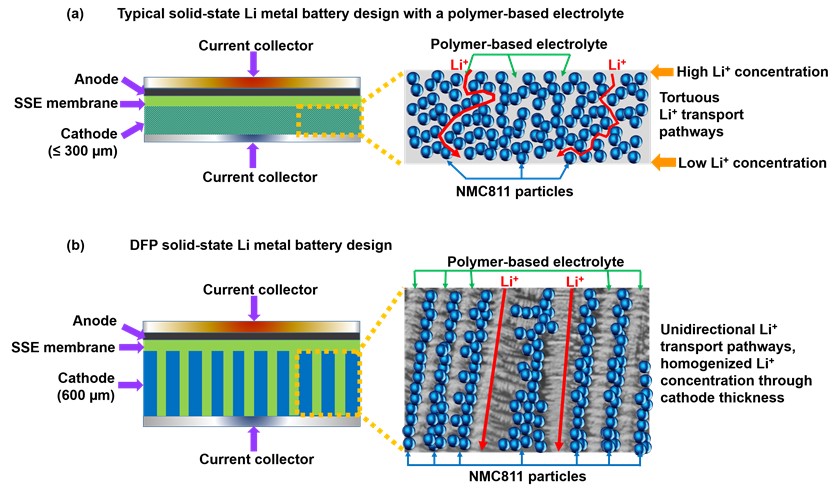

However, the Li+ ion diffusivity in a composite cathode—a combination of active material and solidstate electrolyte (SSE)—is at least an order of magnitude lower than that of the SSE alone because of the highly tortuous ion transport pathways in the cathode This lowers the realizable capacity and mandates relatively thin (30–300 μm) cathodes, and hence low overall energy storage.

King’s researchers are developing, a thick (600 μm) hybrid cathode comprising vertically aligned LiNi0.8Mn0.1Co0.1O2 (NMC811)-rich channels filled with a [LiTFSI+PEGMA+MePrPyl TFSI] polymer composite electrolyte that is fabricated by an innovative directional freezing and polymerization method.

The global lithium-ion battery market size is projected to grow from USD 41.1 billion in 2021 to USD 116.6 billion by 2030; it is expected to grow at a CAGR of 12.3% from 2021 to 2030– Marketsandmarkets.com

Figure 1. Schematic diagrams of a) a typical solid-state Li metal battery (SSLMB) design that uses a polymer-based electrolyte with a randomly mixed cathode structure (⩽300 μm thick) involving tortuous percolative Li+ ion transport pathways through the inter-connected SSE; b) the SSLMB design with an anisotropic cathode structure (600 μm thick) comprising vertically aligned NMC811-rich pillars surrounded by a polymer-based electrolyte

Applications:

In almost every area of today’s society “batteries “ provide essential duties in powering our devices, storing our energy and protecting our assets.

Batteries for the smallest application in medical devices personal fitness devices

Batteries for portable electronics, e.g., mobile phones, iPad, laptops, etc.

Batteries for electric transportation, e.g., electric vehicles, drones, electric powertrain, etc.

Batteries for large electrical energy storage systems, e.g., energy storage system of electricity generated on solar farm, wind farm, Tidal.

As we progress towards Net Zero the challenges are immense the conversion of current energy use to low carbon will take significant investment, regulation and innovation. However, batteries have already made a significant impact with most car manufacturers expecting more than 30% of their fleets to be electric by 2030.

The key limiting factors for EV adoption are battery safety and requirement for higher specific energy the solution: This invention prevents battery combustion incidents and increases battery specific energy from 250-300 Wh kg-1 to 500 Wh kg-1

Advantages:

Comparing this invention with commercial lithium ion battery (LIB):

• This SSB is safer to operate, because commercial LIB uses a flammable liquid electrolyte whereas this SSB uses a non-flammable solid-state electrolyte (SSE).

• The proposed SSE material is more stable than the liquid electrolyte thus able operate at a higher voltage.

Comparing this invention with other SSB’s in development:

• The proposed SSE material exhibited a higher ionic conductivity (2.2x10-3 S cm-1) than other SSE materials (1 x 10-5 – 7 x 10-4 S cm-1).

• Reduced ion transport pathway tortuosity from 3.3-4.9 to 1.2, and increased ion flux by 81%.

• Increased ionic conductivity and ion flux increased specific capacity by 35% (achieved 99% of the electrode theoretical capacity).

This invention makes solid-state batteries that use a non-flammable, new solid-state electrolyte (SSE) material to replace the standard liquid electrolyte.

Across all the market segments where batteries are being used and developed the ability to reduce size and weight while improving energy density opens up limitless applications.

Implantable devices can be further miniaturised Household Solar Panels and their storage batteries are reduced in footprint.

Even large storage facilities have a reduced footprint and perhaps most importantly the costs and energy used in transporting battery mass is reduced Both in actual vehicles and their daily use but also in battery supply chains.

The ‘proof of concept’ of the SSLMB technology has been demonstrated and the Kings team is looking for support both in funding and commercialisation in a variety of sectors. Please contact us for more information.